RS wheel-rail measurement

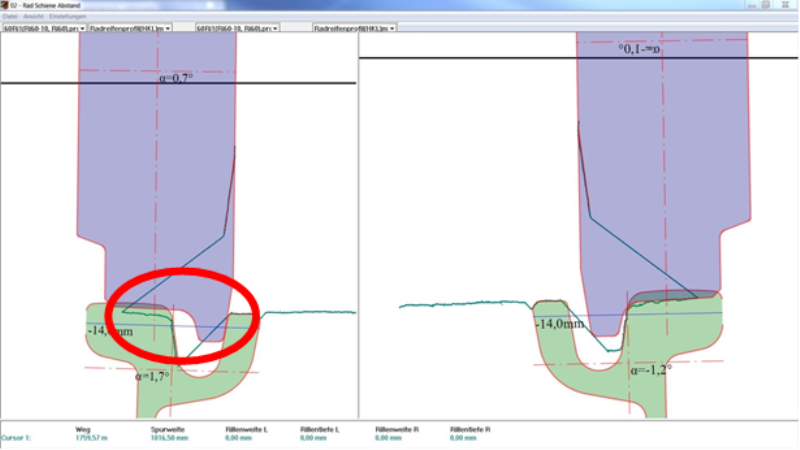

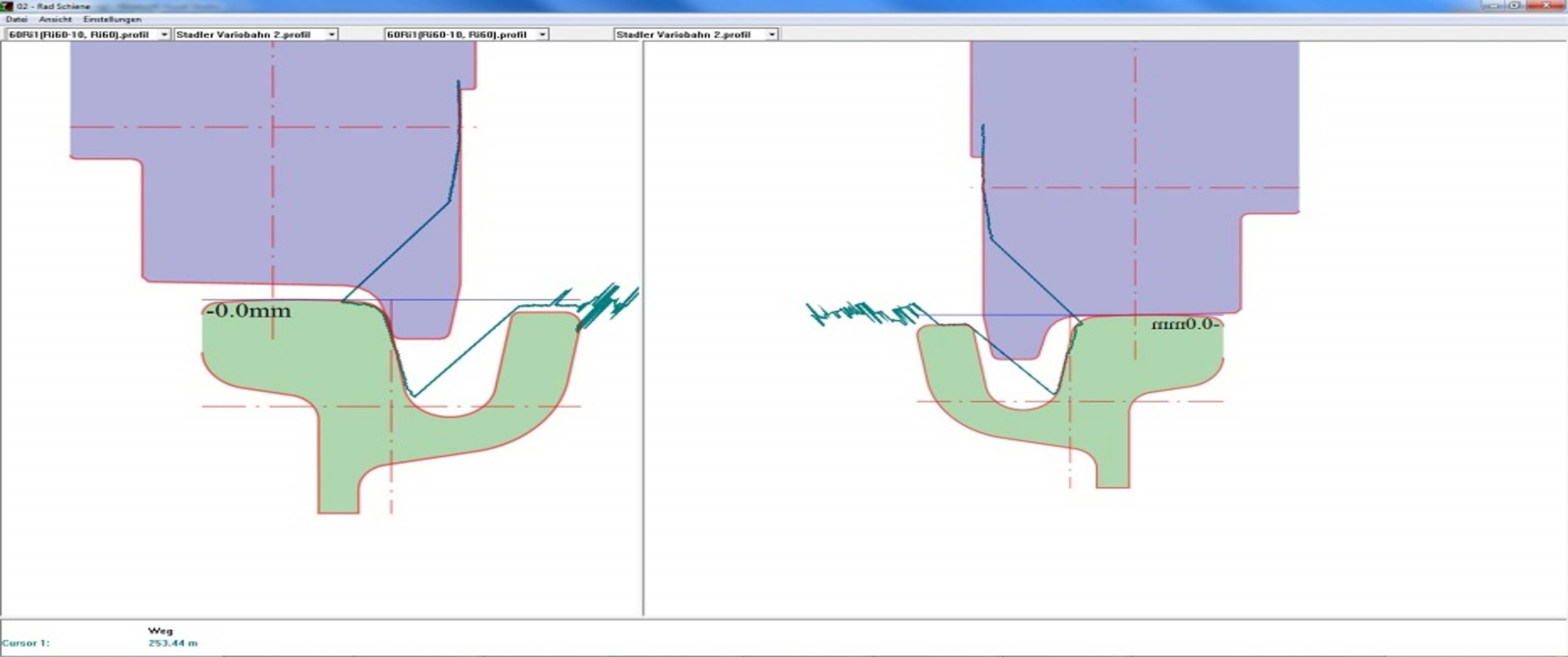

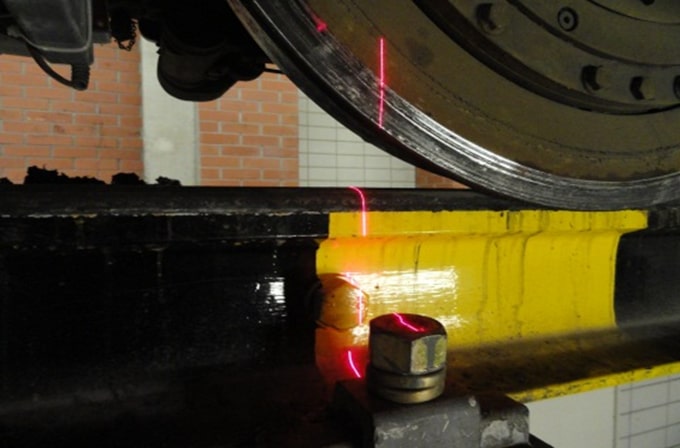

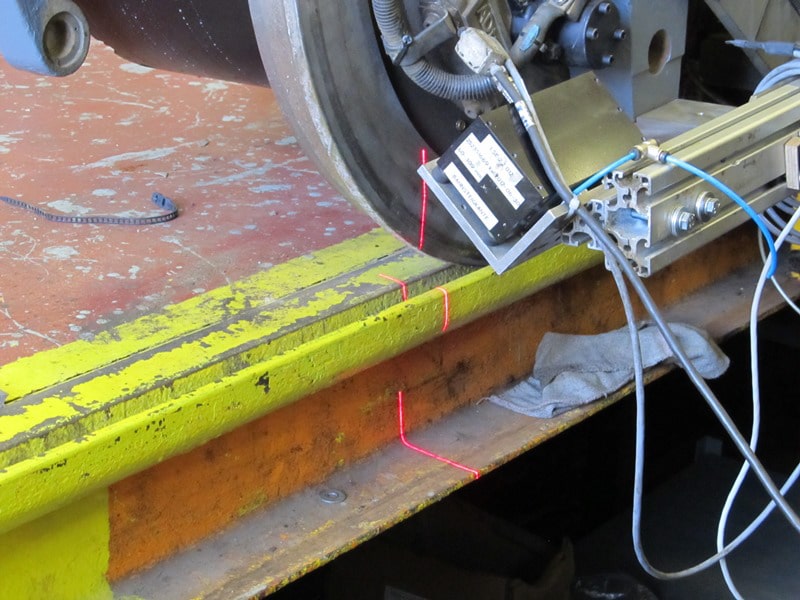

Our Wheel-Rail Measuring System captures the interaction between railway wheels and the rail, enabling the determination of the sinusoidal running of the wheels. It detects possible profile deviations and potential two-point contacts between wheel and rail, which can increase wear on wheels and rails and lead to high noise levels.