3S Third Rail Measurement Contactless

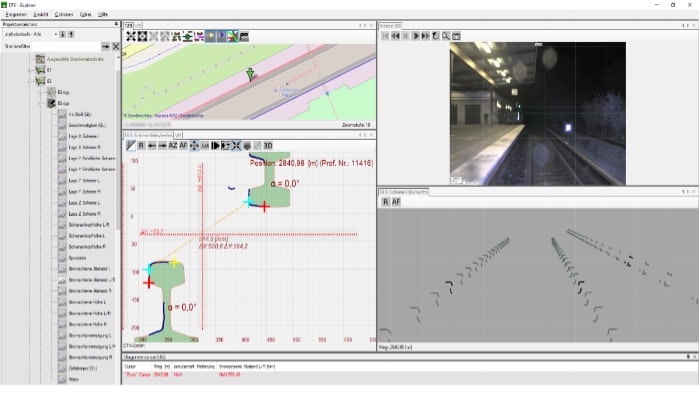

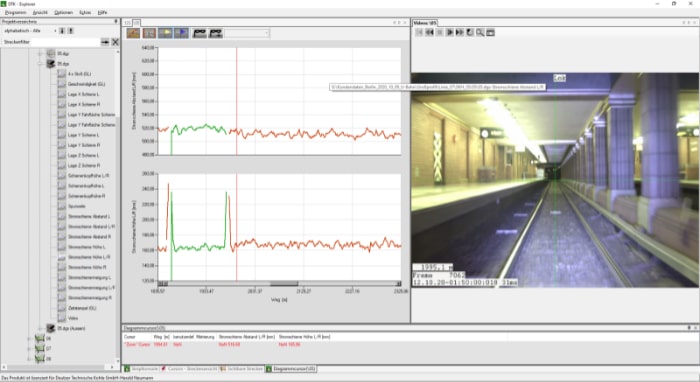

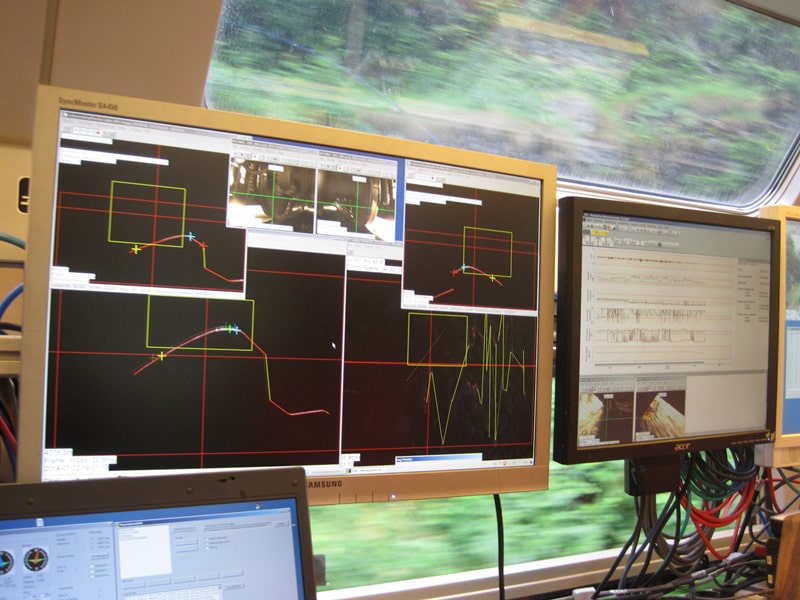

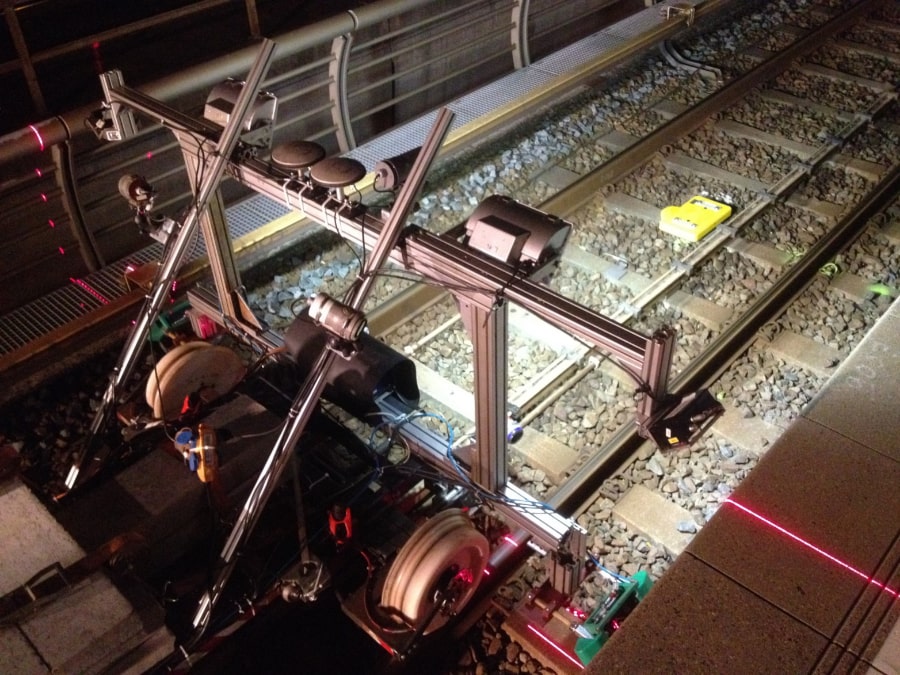

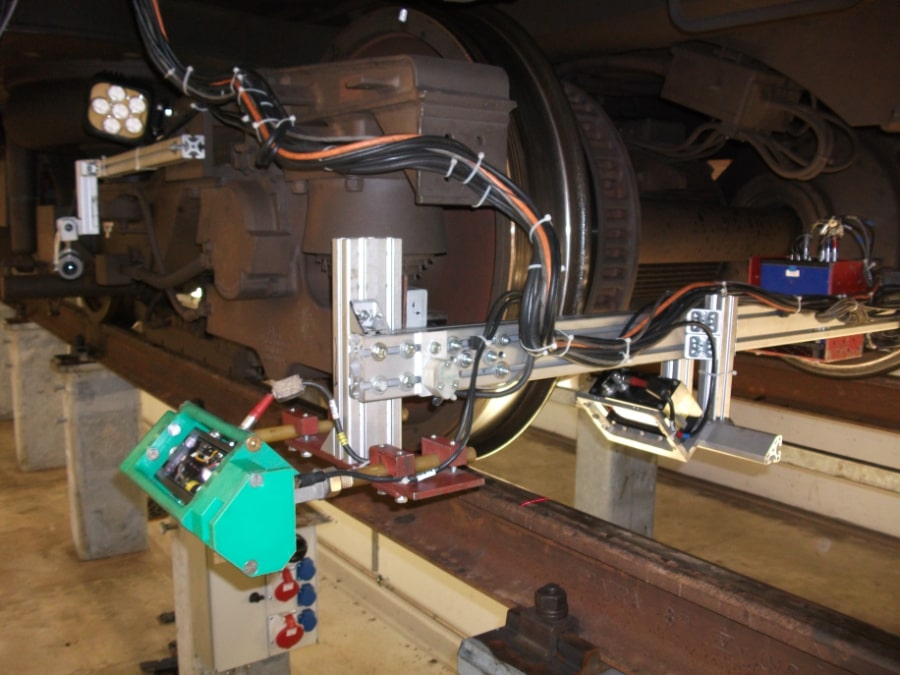

Our contactless measurement system uses laser profile scanners to capture the contour of the third rail, thereby providing precise information about its height, lateral position, and wear condition. The DTK system “Third Rail” enables an effective assessment and optimization of the interaction between the current collector and the conductor rail.