OB Trolleybus Contact Wire Thickness

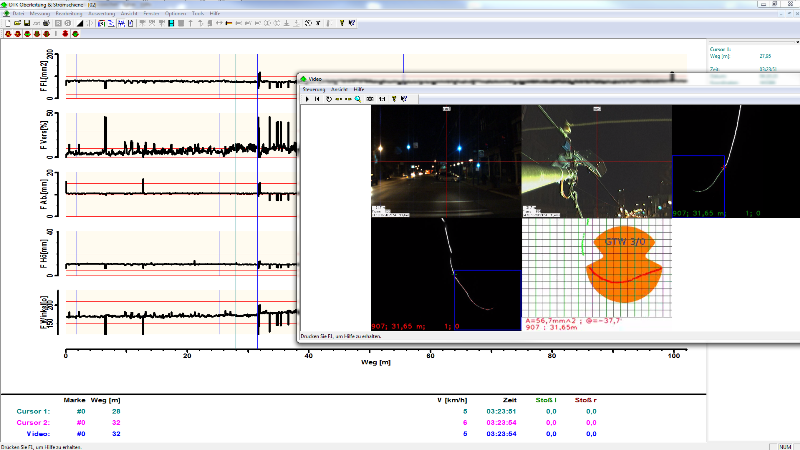

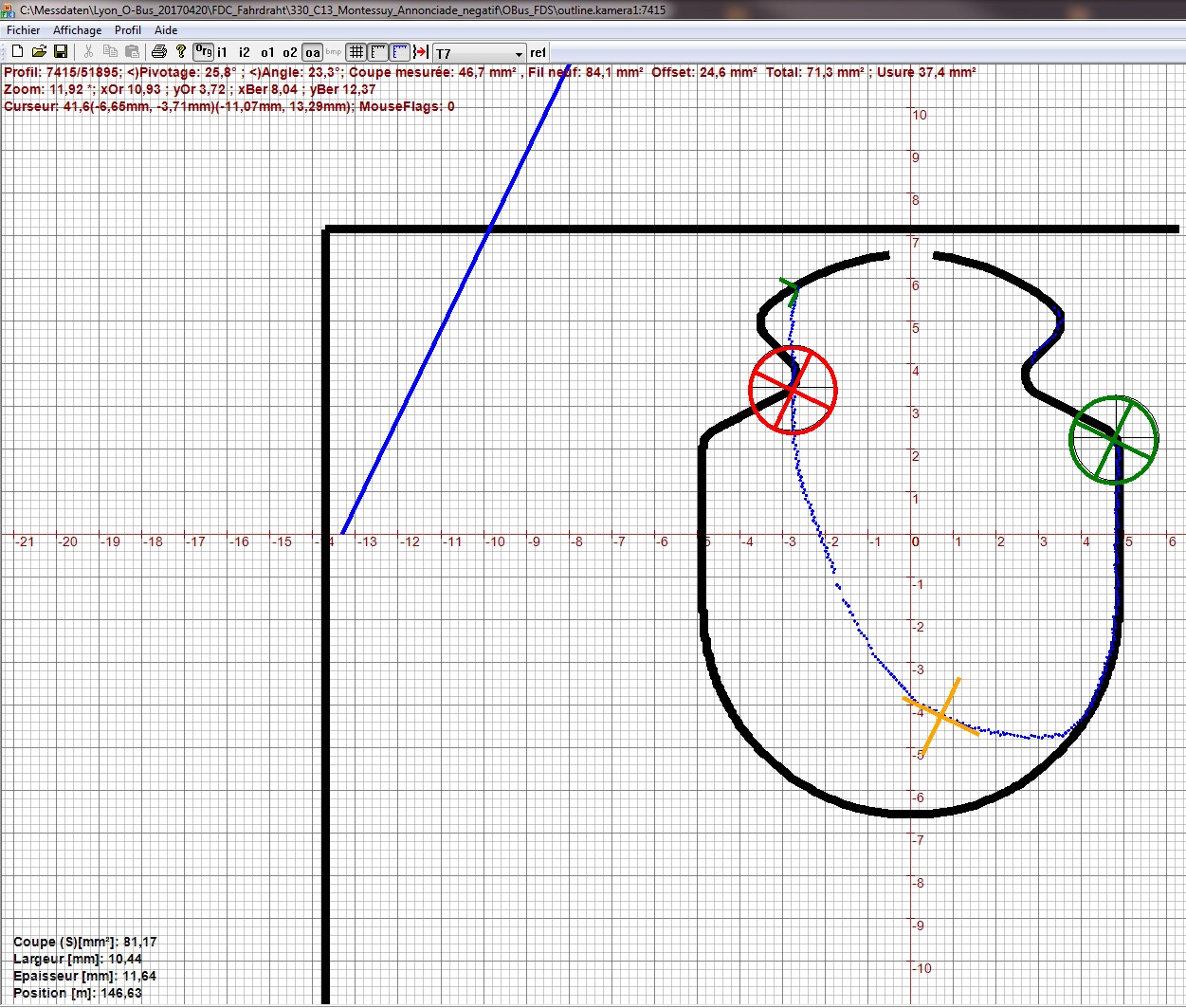

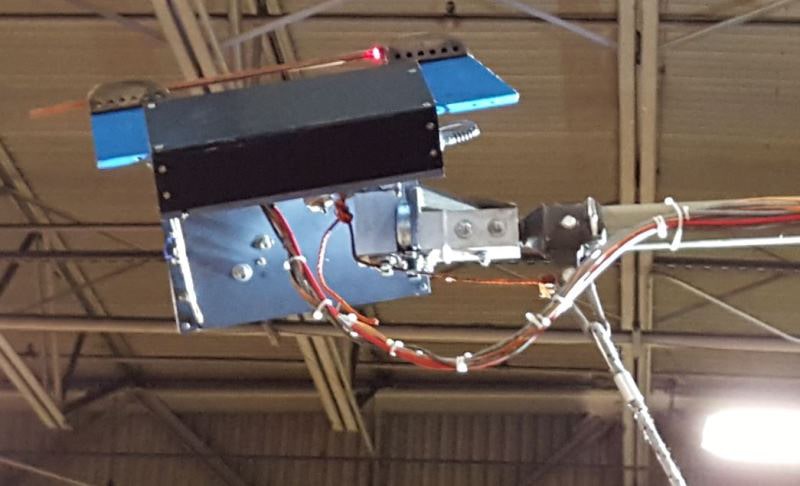

The DTK “Trolleybus Overhead Wire Profile Measurement” system allows for precise assessment of the condition of trolleybus overhead wires, including the wire contour, wire twist, wire wear, and position on the route. In addition to measuring the wire profile, it also identifies locations where impacts in the wire occur to precisely locate defects.