FDS4 overhead wire measurement

The DTK system FDS4 is an optical measuring system that is used to check the contact wire contour and thus the wear condition of contact lines at transport companies.

The DTK system FDS4 is an optical measuring system that is used to check the contact wire contour and thus the wear condition of contact lines at transport companies.

The DTK System FDS4 is an optical measuring system used to test the contour of overhead contact wires and thus the wear condition of catenary systems in transport companies.

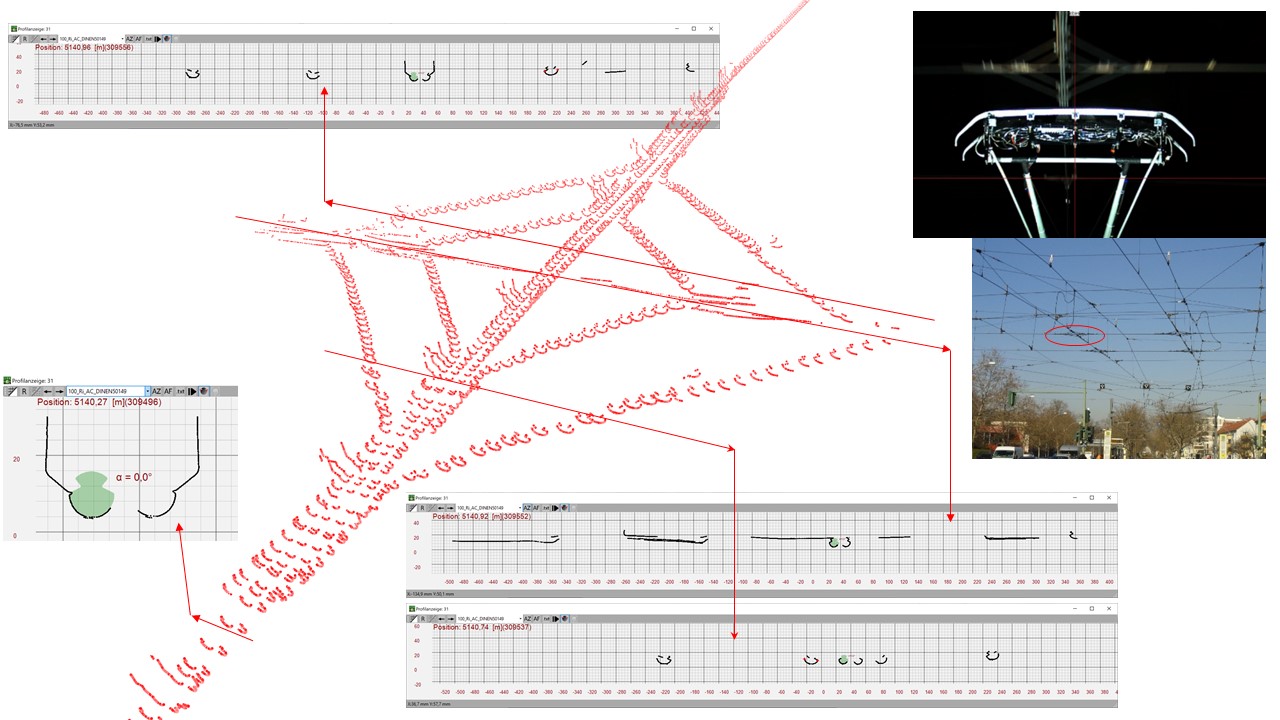

The FDS4 is the only measuring system that captures the entire profile of a contact wire from a moving train.

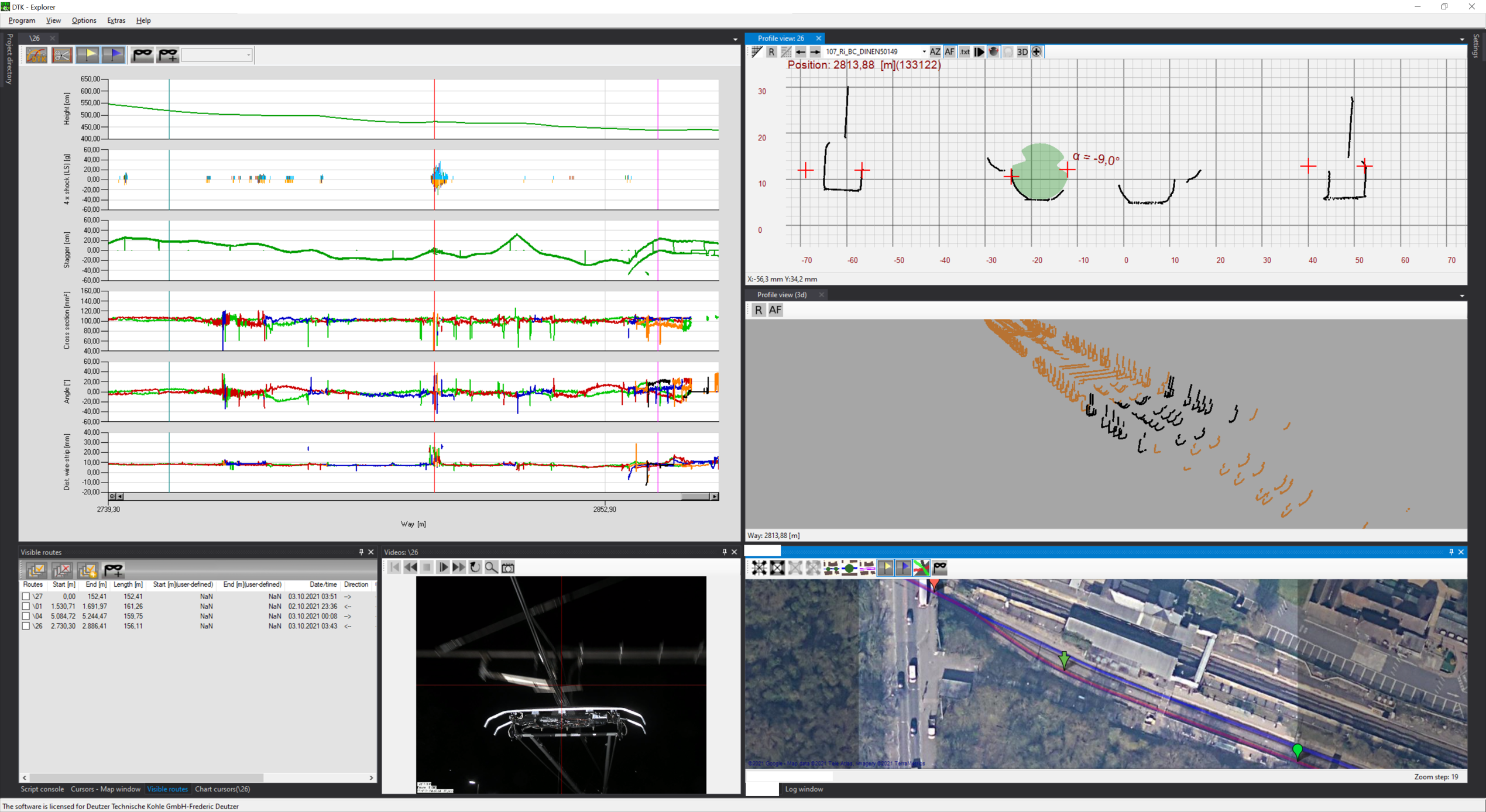

It measures various parameters such as wire wear, wire contour, wire twist, wire height, wire gradients, stagger,

impacts between pantograph and contact wire, as well as the entire profile of catenary components, and the position

on the track and speed. Additionally, recorded videos show the interaction between pantograph and contact wire.

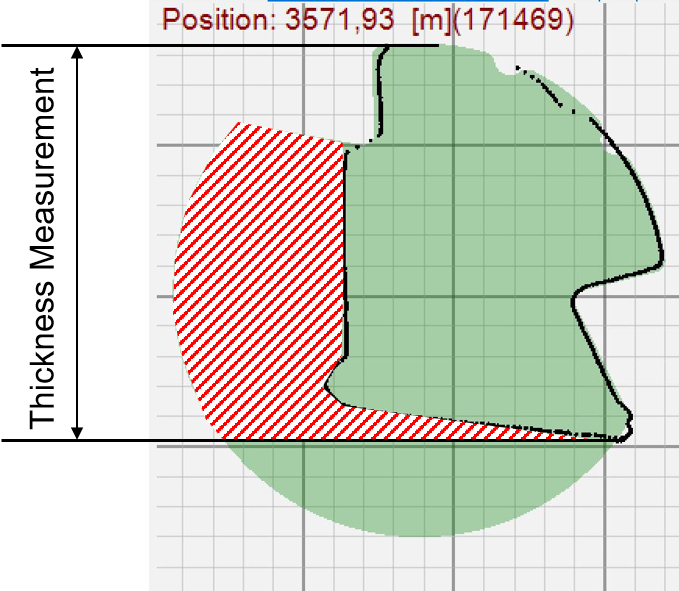

The system’s evaluation software displays the actual contact wire contour and allows for a visual comparison with the new contour.

The computer determines the cross-section in square millimeters. This is more reliable than traditional measuring methods, such as measuring the contact surface or the remaining thickness from the side, as these only account for wear from below and many safety-critical faults found by the FDS4 could not be detected with wear pattern or remaining thickness measurements.

More than 100 measurement campaigns at over 50 transport companies have already been conducted with this measuring system.

The GPS data enables a convenient display of deviations in a map view and user-friendly evaluation in the DTK Software Explorer. Exporting the data to own databases or for further use is also possible.

Overall, the DTK System “FDS4” offers the most reliable and user-friendly solution for testing overhead contact wire systems.

Optionally, vehicle sway can also be recorded to capture the static contact wire position.

Components and markings next to the track can also be captured to obtain additional local references.

Measurement frequency: 320 Hz (optional 400Hz)

Measurement tolerance: +/- 3% of the cross-section [mm²]

Lateral position: +/- 0.2 mm

Height position: +/- 2 mm